Black Belt Excellence

You are here: Programs & Courses » Open Certificate Courses » Black Belt Excellence

Become an Expert in Data-driven Process Optimization

The Black Belt Excellence training is designed for professionals from various fields, including process improvement, quality management, operations, supply chain, IT, business analysis, project management, consulting, and data analytics. Specifically tailored for Process Owners/Experts, Operations Analysts, Quality Process Managers, and Project Managers/Internal Consultants focused on processes, courses equip participants with the skills needed to thrive in today’s data-driven business landscape. Whether individuals aim to enhance analytical capabilities, optimize processes, or drive organizational excellence through data-driven insights, this course offers a transformative learning experience for professionals across diverse roles and industries.

A Black Belt course is an advanced training in Lean Six Sigma, a methodology aimed at improving business processes by reducing waste and defects. This Lean Six Sigma Black Belt course is designed for professionals who want to lead and manage complex improvement projects within their organizations.

Key Facts

Course period

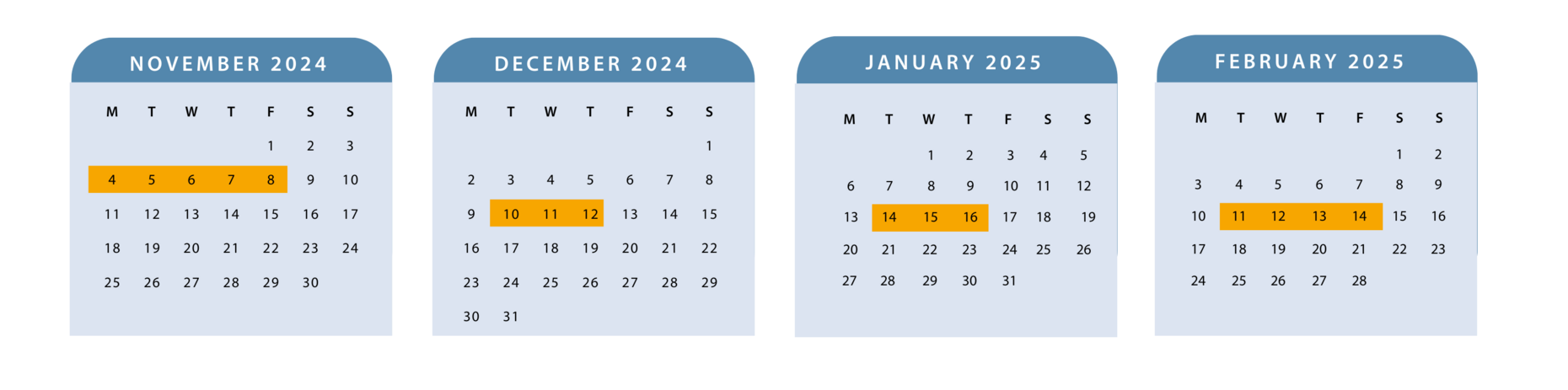

November 2024 – February 2025

Course Fee

€9,995 including all courses and materials, 8 coaching hours and meals during the modules

Location

On site, Mannheim, Germany

Prerequisites

None

Certificates

Graduates are awarded certificates by both Mannheim Business School and The Lean Six Sigma Company

Language

English

Structure

12 days of Black Belt training including exam with an extra 3 days of Process Mining

8+ hours of personalized coaching by a Master Black Belt

Reputation

Internationally recognised certificate

Key Benefits at a Glance

Complete Lean Six Sigma program

Optimal balance of theoretical and practical elements

Direct, measurable impact for organizations

1-to-1 project coaching

Access to an extensive network

Exclusive MyTraining™ learning platform

Internationally recognized certificate

Program Overview

Participants will delve into process mining, exploring event data extraction, process discovery, conformance checking, and performance analysis. The program also touches on how process mining can be integrated with modern machine learning techniques for even deeper insights. By the end of the course, participants will come to possess a solid foundational understanding of data-driven process optimization, in order to significantly contribute to their organization’s goals.

Schedule

Course Overview

Lean

The course aims to provide an overview of process improvement by introducing the concept of lean and its five principles: identifying customer value, analyzing the value stream, ensuring flow, implementing pull systems, and striving for perfection. Participants will gain an understanding of processes, their importance, and potential challenges. They will also learn about Lean philosophy, identifying bottlenecks, applying the Theory of Constraints, determining customer value-add steps, creating value stream maps, assessing flow efficiency, calculating Takt-time, WIP, and PLT using Little’s Law, and applying methods such as 5S, Poka Yoke, Kaizen Events, and visual management techniques.

November 4–6, 2024

Six Sigma

During the Six Sigma days of our Black Belt Excellence program, you can expect a thorough exploration of the methodology’s origins and operational structure. You’ll learn about its inception at Motorola and widespread adoption by industry leaders like General Electric. Through engaging sessions, you’ll understand the roles and responsibilities within a Six Sigma organization, enabling you to drive impactful improvements in process mining projects, ensuring efficiency and quality.

November 6, 2024

DMAIC Cycle

During the Six Sigma days of our Black Belt Excellence program, you will delve into the DMAIC approach, a structured problem-solving method. In the Define phase, you’ll determine critical aspects of product/service quality for customers, create Project Charters, and employ tools like SIPOC for process mapping. The Measure phase involves setting measurable outputs, defining improvement goals, and conducting data analysis. Moving to the Analyze phase, you’ll identify root causes using tools such as Fishbone diagrams and FMEA, while also understanding Confidence Intervals. In the Improve phase, you’ll experiment with solutions, utilize Design of Experiments, and employ techniques like brainstorming and benchmarking. Lastly, in the Control phase, you’ll develop Control Plans, implement Lean tools, and ensure effective project handover with thorough documentation. This comprehensive approach equips you to drive impactful improvements in data analyzing projects, ensuring efficiency and quality.

November 7–8, 2024

December 10–11, 2024

February 12, 2025Statistics

During the statistics part of our Black Belt Excellence program, you will gain a comprehensive understanding of descriptive statistics such as mean, median, mode, standard deviation, and variation range, among others. Practical implications of variation will be explained, enabling you to assess sample quality and quantity effectively. You’ll learn to recognize different data types, create data collection plans, and utilize statistical software like Minitab for analysis. Tools for evaluating measurement variation and assessing measurement system capability, such as Gage R&R studies, will be covered extensively. Additionally, you’ll delve into baseline process performance analysis and process capability calculations. Understanding hypothesis testing, including alpha and beta risks, will be emphasized, along with formulating and evaluating null and alternative hypotheses. Lean tools like SMED and OEE will also be introduced to analyze and address lost time in processes effectively. This statistical knowledge equips you to make informed decisions and drive improvements in data engineering projects with precision and accuracy.

November 7–8, 2024

December 10–12, 2024

February 11, 2025Process Mining

During the process mining segment of our Black Belt Excellence program, you will grasp the fundamental concept, relevance, and potentials of process mining, which involves analyzing event logs to improve processes. Key process mining terminology will be explained, alongside understanding the structure and purpose of process event logs. Through hands-on exercises, you’ll learn to characterize processes based on event logs, discover process models, and analyze process-related KPIs. Additionally, you’ll apply rule checking to identify compliance violations, pinpoint bottlenecks, and uncover improvement opportunities within processes. Practical aspects include setting up and managing process mining projects, complemented by a guest lecture from industry experts like Celonis, followed by a comprehensive case study in the Celonis system. Finally, technological advancements in process mining, such as robotic process automation and machine learning applications, will be explored, discussing their applicability and limitations. This knowledge equips you to leverage process mining techniques effectively in real-world scenarios, driving efficiency and optimization in data analysing projects.

January 14–16, 2025

Exam & Review

During the exam and review portion of our Black Belt Excellence program, participants will engage in a comprehensive review of the course material, ensuring a thorough understanding of Lean Six Sigma principles and methodologies. The culmination of the program is the Lean Six Sigma Black Belt Exam, where participants will demonstrate their ability to execute Lean Six Sigma projects, facilitate improvement teams, apply Lean Six Sigma tools effectively, and implement successful solutions within organizational contexts. Upon completion of this final day, participants will be equipped with the knowledge and skills necessary to drive impactful improvements and lead data engineering projects with confidence and competence.

February 14, 2025

Faculty

Prof. Dr. Jana Rehse

Prof. Dr. Jana-Rebecca Rehse is an Assistant Professor for Management Analytics at the University of Mannheim. She is a leading expert in Management Analytics, specializing in the application of Artificial Intelligence (AI) to enhance business processes. With a doctoral degree in Business Administration from Saarland University and a track record of prestigious awards, she has significantly contributed to research areas including process mining, machine learning for process prediction, and domain-specific process assistance systems. Her influential publications, such as those in Business & Information Systems Engineering and ACM Transactions on Management Information Systems, underscore her impact in advancing AI-driven approaches for business process optimization.

Steve Cook

As a long-time Six Sigma Master Belt and quality professional, Steve Cook has developed his continuous improvement process (CIP) skills throughout his professional life. By leading excellence projects, he not only strives for process improvements, but also works closely with the people within the organization to develop sustainable solutions that contribute to the success of the company and its customers.

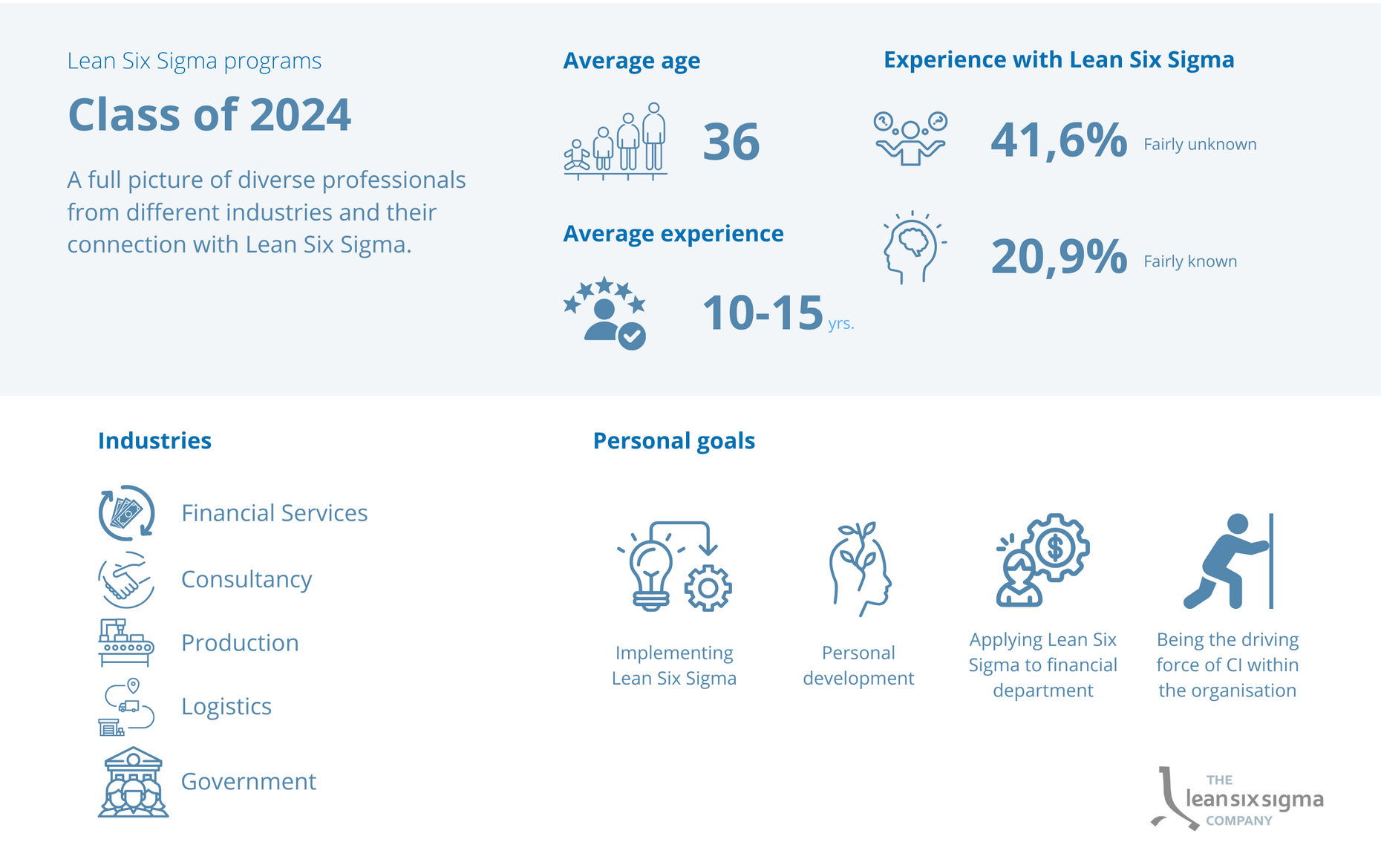

Cohort Overview

Registration and Contact Person

Would you like to receive more information by phone about our Black Belt Excellence program? Get in touch with Helen Brokking at The Lean Six Sigma Company.

+49 (0)211 – 8694 3097

info@theleansixsigmacompany.de

Please register for the Black Belt Excellence Course via www.theleansixsigmacompany.de/black-belt-excellence/

Good to know: Tax offices usually recognize costs for your further education if they are job-related. Please note: Each federal state in Germany has regulations on educational leave. Check here to see which regulations apply in your federal state and get in touch with us to discuss your individual situation.

Contact Person Mannheim Module